Cygnus 1 Ex

Advanced Intrinsically Safe UTG

- AVAILABLE TO ORDER – NEW Cygnus High Temperature Ex Probe.

The Cygnus 1 Ex Ultrasonic Thickness Gauge is a rugged, handheld, intrinsically safe instrument designed for taking reliable thickness measurements in Zone 0 Explosive Atmospheres – making it ideal for use in fuel depots, road and vessel tankers, mines, chemical plants, oil and gas, refineries, pipelines, hazardous storage tanks and other hazardous environments.

Key Features:

- Certified Intrinsically Safe to ATEX, IECEx, UKEX for Zone 0

- Continuous measurement on hot assets in-service, using the NEW Cygnus High Temperature Ex Probe

- Intrinsic Safety protection – No need for hot work permits

- 3 measuring modes for levels of corrosion, various materials and through-coat measurements

- Deep Coat function ignores thick coatings

- Manual Measurement Mode allows gates and gain to be configured to suit your application

- Live A-Scans aid visual measurement verification

- Live B-scans give a quick, cross-sectional representation

- 4 function keys for easy controls and dynamic views

- User Access feature protects records with correct user access levels

- Measurement setup can be saved and restored for a quick start

- Measurement Freeze function and Ref/Min/Max thickness limits

- A solid-state electronic instrument with a rugged IP67 rated enclosure

- Bluetooth connection for transferring data to CygLink

- Available as SC, TC, PLUS and PRO variants with options of upgradeable features (download the Cygnus 1 Ex Variants Comparison Guide).

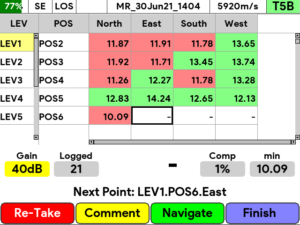

| Measuring Modes | Single Echo with Twin Crystal Probes Echo-Echo with Twin Crystal Probes Multiple Echo with Singly Crystal Probes |

| Materials | Sound velocity from 1000 m/s to 9000 m/s [0.0390 in/us to 0.3543 in/us] |

| Accuracy | ±0.1 mm (±0.004”) or 0.1% of thickness measurement whichever is the greatest |

| Resolution | 0.1mm, 0.05mm or 0.01mm depending on probe type |

| Probe Options | Single crystal and twin crystal probes |

| Measurement Range in Steel | 0.8mm to 250mm (0.031 in. – 10 in.) depending on selected probe and configuration, material and temperature |

| Connector | Single Dual Coaxial Connector |

| Power Supply | Rechargeable, removable Lithium-Ion battery pack |

| Power Rating | 2W |

| Probe Sockets | Single Dual Coaxial Connector |

| Battery Life | 6-8 hours continuous measurement |

| Display | 3.5” VGA, sunlight readable colour display |

| Size | 270mm tall, 135mm wide, 80mm deep |

| Weight | 1 kg with battery |

| Operating Temp. | -0°C to +50°C (32°F to 122°F) |

| Storage Temp. | -10°C to +65°C (50°F to 149°F) |

| Data Logging | 10,000 measurements and A-scans per record |

| Computer Software | CygLink allows remote logging and viewing of A-scan graphs. Survey and report generation to PDF file. Graphic analysis of data and statistical calculations. Bluetooth connection to transfer data to a Windows® computer with CygLink. |

| Certification | ATEX, IECEx and UKEX I M1 Ex ia Ma (Tamb = 0°C to +50°C) II 1G Ex ia IIC T4 Ga (Tamb = 0°C to +50°C) Certificate Numbers; ATEX: ExVeritas 21ATEX0860X UKEX: ExVeritas 21UKEX0861X IECEx: IECEx EXV 21.0035X |

| Environmental Protection | IP67 Pollution degree 3 |

| Standards | Designed for BS EN 15317:2000 |

| Warranty | 3 years on gauge and 6 months on probe |

| Weight | 5 kg |

| Kit | Cygnus 1 Ex – SC (Single Crystal) Variant Kit WITHOUT PROBE (060-1105), Cygnus 1 Ex – TC (Twin Crystal) Variant Kit WITHOUT PROBE (060-1110), Cygnus 1 Ex – PLUS Variant Kit WITHOUT PROBE (060-1115), Cygnus 1 Ex – PRO Variant Kit WITHOUT PROBE (060-1120) |

Single crystal probes (Probe Sxx) are compatible with all Variants, except TC Variant.

Twin crystal probes (Probe Txx) are compatible with all Variants, except SC Variant.

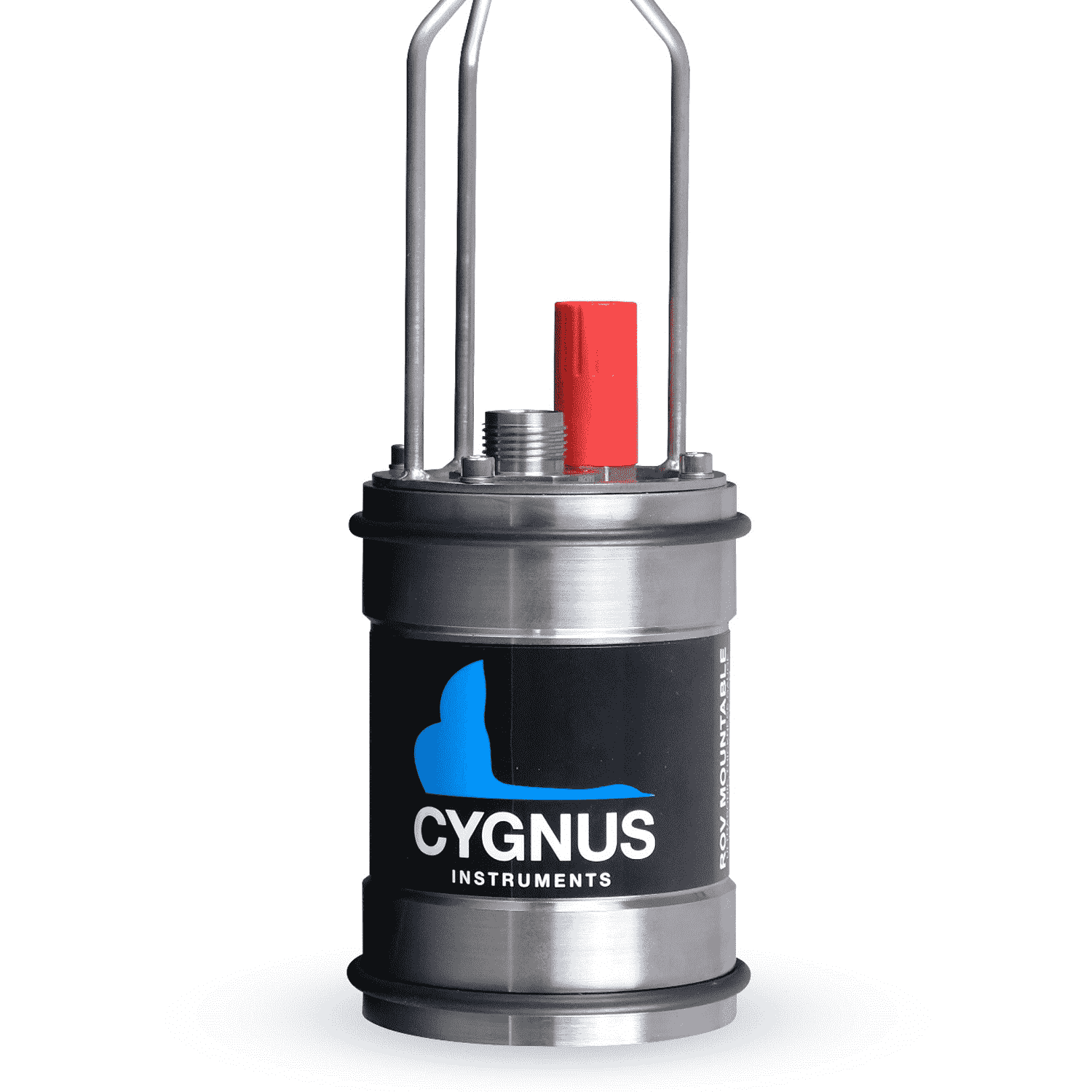

Twin element high temperature Ex probe

Cygnus 1 Ex Variants Comparison Guide

Cygnus High Temperature Ex Probe Brochure

Cygnus Surface Gauge Family Brochure

2 reviews for Cygnus 1 Ex

Dennis H.

Jul 11, 2023 8:35 AM

In march 2023 we have bought another one, this is for ourselves in our hire fleet.

We have had several customers and we are also very satisfied with the instrument.

We think the instrument is versatile, multifunctional, robust and intuitive..

Michel Kramer Freher

Oct 12, 2023 11:05 AM

Almost a year ago we purchased two Cygnus 1 Ex thickness gauges because of urgent need to provide our customer base UT wall thickness data in ATEX zone 1 and 0. To our knowledge the Cygnus 1 Ex is the only ATEX zone 0 gauge with A-screen for peek-to-peek measurements. We have been using the equipment during in-service storage tank and piping inspection and our operators we very pleased using it. Also the UT thickness data is quite easy to retrieve into excel or csv format for efficient reporting. Last but not least; quality to price ratio is great. Suggestion for improvement is that we would like to see corrosion examination would be made available through a suitable probe set up.