Cygnus 2+ Hands Free

Ultrasonic Thickness Gauge

The Cygnus 2+ Ultrasonic Thickness Gauge is specifically designed for hands-free use by displaying measurements via an end-mounted screen. With three measuring modes, it measures the wall thickness of a variety of materials (including plastics) and metals of any level of corrosion and pitting. This hands free UTG is ideal for rope access, hull UTM inspection, civil engineering, marine structures, structural integrity inspection via rope access or climbing, heavily corroded metals with front/back wall pitting, irregular geometric shapes, attenuative materials and ship surveys.

Key Features:

- Multiple-Echo mode for accurate, through-coat measurements as specified by Classification Societies

- Echo-Echo and Single-Echo modes for heavily corroded metals with a thin or no coating

- Hands free operation: wrist, waist belt and harness mountable

- End-Mounted display shows thickness measurements – ideal for rope access or climbing work

- Front display enables easy gauge setup

- Deep Coat function ignores coatings up to 20mm thick

- MSI (Measurement Stability Indicator) verifies stable, reliable readings

- Intuitive easy to use menu

- Extremely rugged enclosure – shock and impact proof to US MIL STD 810G

- Environmental sealing (water and dust proof) to IP67 – US MIL STD 810G

- Uses single and twin crystal probes

- Can be upgraded to 4+ or 6+ at an additional cost.

| Measuring Modes | Multiple-Echo using 3 echoes to ignore coatings up to 20 mm (0.8 inch) thick Echo-Echo using 2 echoes to ignore coatings up to 1 mm (0.04 inch) thick Single-Echo using 1 echo |

| Materials | Velocities from 1,000 – 9,000 m/s (0.0390 – 0.3543 in/us) |

| Accuracy | ±0.05 mm (±0.002”) – in Multiple-Echo measurement mode, when calibrated and measuring the same material as calibrated on ±0.1 mm (±0.004”) or 0.1% of thickness measurement whichever is the greatest – in Single-Echo & Echo-Echo measurement modes, when calibrated and measuring the same material as calibrated on |

| Resolution | Multiple-Echo mode – 0.1 mm (0.005 inch) or 0.05 mm (0.002 inch) Single-Echo and Echo-Echo modes – 0.01 mm (0.005 inch) or 0.01 mm (0.001 inch) |

| Probe Options | Single crystal probes and Twin crystal probes |

| Measurement Range in Steel | 0.8 – 250 mm (0.031 – 10 inch) depending on selected probe and configuration, material and temperature |

| Connector | 2 x Lemo 00 |

| Power | 3 x AA / R6 batteries |

| Battery Life | Approx. 10 hours continuous measurement |

| Electronics | Dual channel pulser |

| Display | End-mounted rotatable LCD: 25.58 x 6.38 mm (for measurements) 2.4” QVGA LCD: 47 x 37 mm (for gauge setup only) |

| Size | 84 x 130 x 35 mm (3.3 x 5.1 x 1.4 inch) |

| Weight | 300 g (10.5 oz) (inc. batteries) |

| Operating Temp. | -10°C to 50°C (14°F to 122°F) |

| Environmental Rating | IP67 MIL STD 810G Method 501.6 (high temp +55°C (131°F)) MIL STD 810G Method 502.6 (low temp -20°C (-4°F)) MIL STD 810G Method 507.6 (humidity 95%) MIL STD 810G Method 512.6 (immersion 1 metre for 30 mins) |

| Shock and Impact | MIL STD 810G Method 514.7 (vibration) MIL STD 810G Method 516.7 (shock 20g) MIL STD 810G Method 516.7 (transit drop 1.22 m) |

| Standards | Designed for EN 15317 |

| Compliance | CE, UKCA, RoHS |

| Warranty | 3 years on gauge and 6 months on probe |

| Weight | 5 kg |

| Kit | Cygnus 2+ Hands Free Standard Kit WITHOUT PROBE (050-2500/5) |

To compliment our ultrasonic thickness gauges we offer a range of ultrasonic probes. The performance of any ultrasonic thickness gauge relies heavily on the probe and its suitability to the material being measured. Therefore, selecting the right probe is vital. All Cygnus’ probes are made from stainless steel and have a hard wear face or a wear membrane to protect the probe.

Variety of Cygnus INOX Probes

- Stainless steel SINGLE CRYSTAL probes, used in multiple-echo mode, include replaceable membranes for long life, require no zeroing and have a high linear accuracy.

- Stainless steel TWIN CRYSTAL probes, used in echo-echo and single-echo modes, have improved measurability on extreme back wall corrosion and pitting.

- Probes for use with the Cygnus 2+, 4, 4+ and 6+ gauges are fitted with a BNC or Lemo 00 connector.

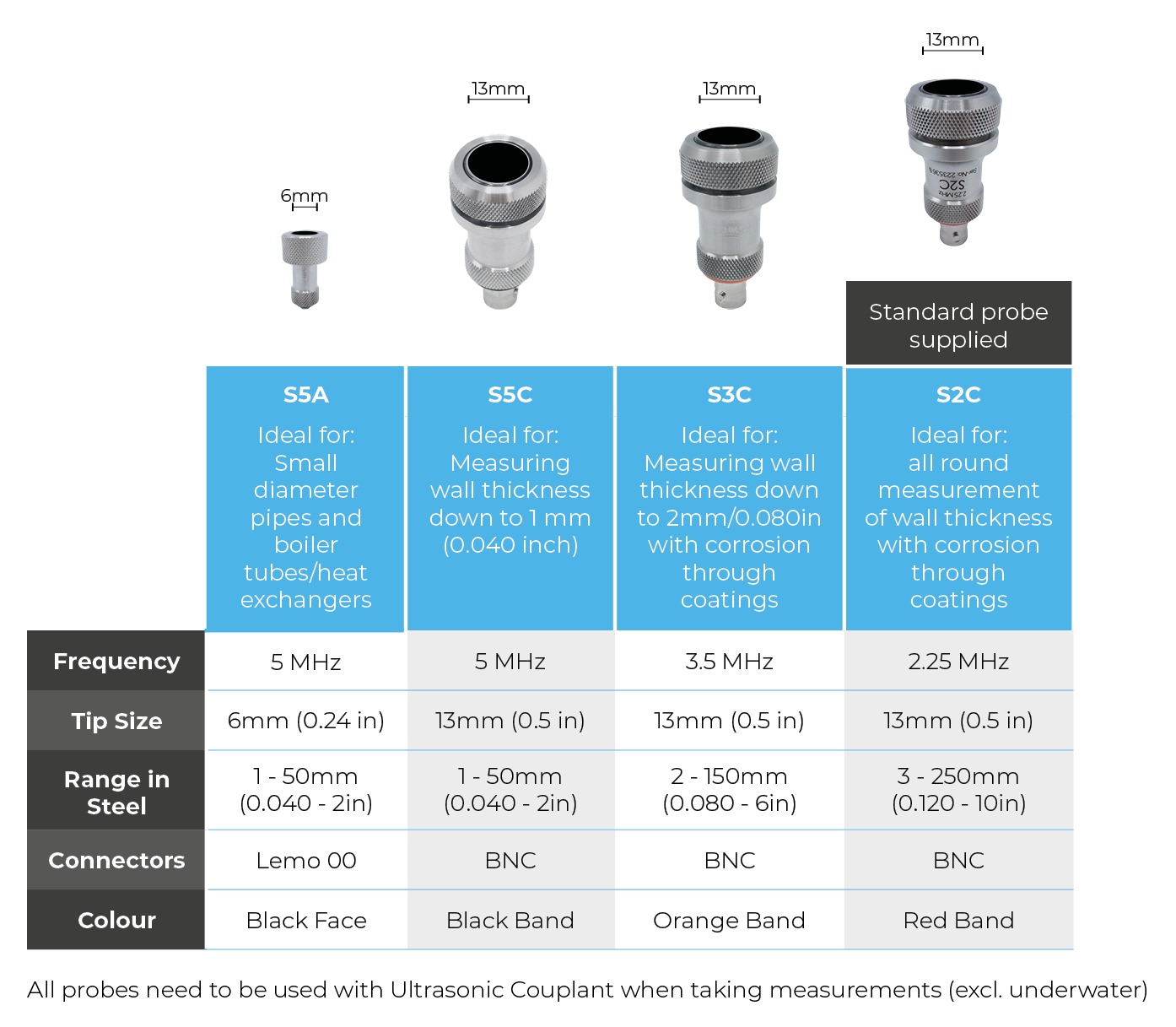

Single Crystal Probes

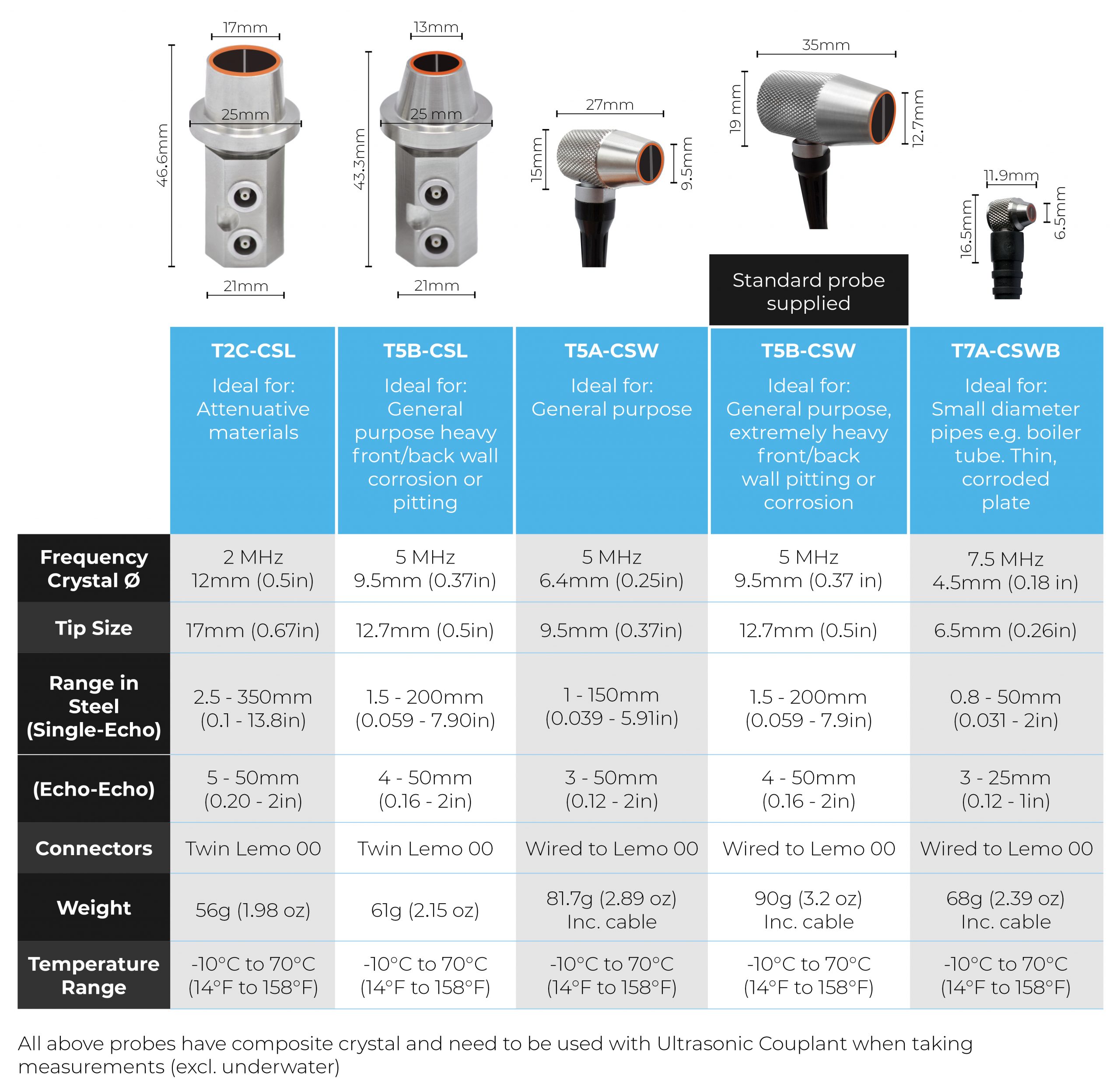

Twin Crystal Probes

Cygnus Surface Gauge Family Brochure

Cygnus Surface Range Comparison Guide

Cygnus 2+ Hands Free – Consumables Reorder Form

5 reviews for Cygnus 2+ Hands Free

MARUTEC

Dec 02, 2015 9:21 AM

We were asked to test the New Cygnus UTM Instruments 2+ and 4+, using their single and twin crystals probes.

Tests carried out in our premises on specially prepared samples and in real working conditions on a 15 years old dry cargo ship of 10.000 M.Tns.

Both instruments, apart they are well designed, they proved to be fast and accurate.

The gauging confirmation through the new measuring experience of MSI System, was a pleasant surprise.

User-friendly with high analysis full coloured LCD screen and very easy menu.

The strong tight case together with the strong cable and its twin lemo locking connector give the immediate impression of the unit being very rugged.

Rafael M.

May 31, 2017 11:54 AM

Believe it or not in the company that I belong to, we have an old one Cygnus 2 (single crystal) since 1990 or less, we compare to other devises that we have and confiability of Cygnus is incredible, there are certain surface that other can not measure. And our Cygnus has not the possibility to calibrate but when we test with the test block always is correct.

David B.

Jan 02, 2018 9:21 AM

Very pleased with the instrument.

Fernando L.

Mar 21, 2019 11:55 AM

Cygnus 2 Hands free is very suitable for UT inspections at hullworks.

Ben E.

Mar 21, 2019 11:56 AM

Haven’t had it long (9 months) but seems reliable and robust, despite being an older model (MK3)