Cygnus 4 General Purpose

Ultrasonic Thickness Gauge

The Cygnus 4 General Purpose thickness gauge uses the Multiple-Echo technique to accurately measure metal thickness without removing protective coatings. This compact gauge is light but tough and truly simple to use with its intuitive menu and is ideal for shipping surveys, plant maintenance, civil engineering, oil and gas, storage tanks and marine inspections.

Key Features:

- Multiple-Echo mode for accurate, through-coat measurements as specified by Classification Societies

- Deep Coat function ignores coatings up to 20mm thick

- Min/Max measurement limit functions

- Visual and vibrate alert

- Simple, one-point calibration – no zeroing required

- Intuitive easy to use menu

- Large and bright front colour LCD display

- Extremely rugged enclosure – shock and impact proof to US MIL STD 810G

- Environmental sealing (water and dust proof) to IP67 – US MIL STD 810G

- Can be upgraded to 4+ or 6+ at an additional cost.

| Materials | Velocities from 1,000 – 9,000 m/s (0.0390 – 0.3543 in/us) |

| Accuracy | ±0.05 mm (or ±0.002 inch) – in Multiple-Echo measurement mode, when calibrated and measuring the same material as calibrated on |

| Resolution | 0.1 mm (0.005 inch) or 0.05 mm (0.002 inch) |

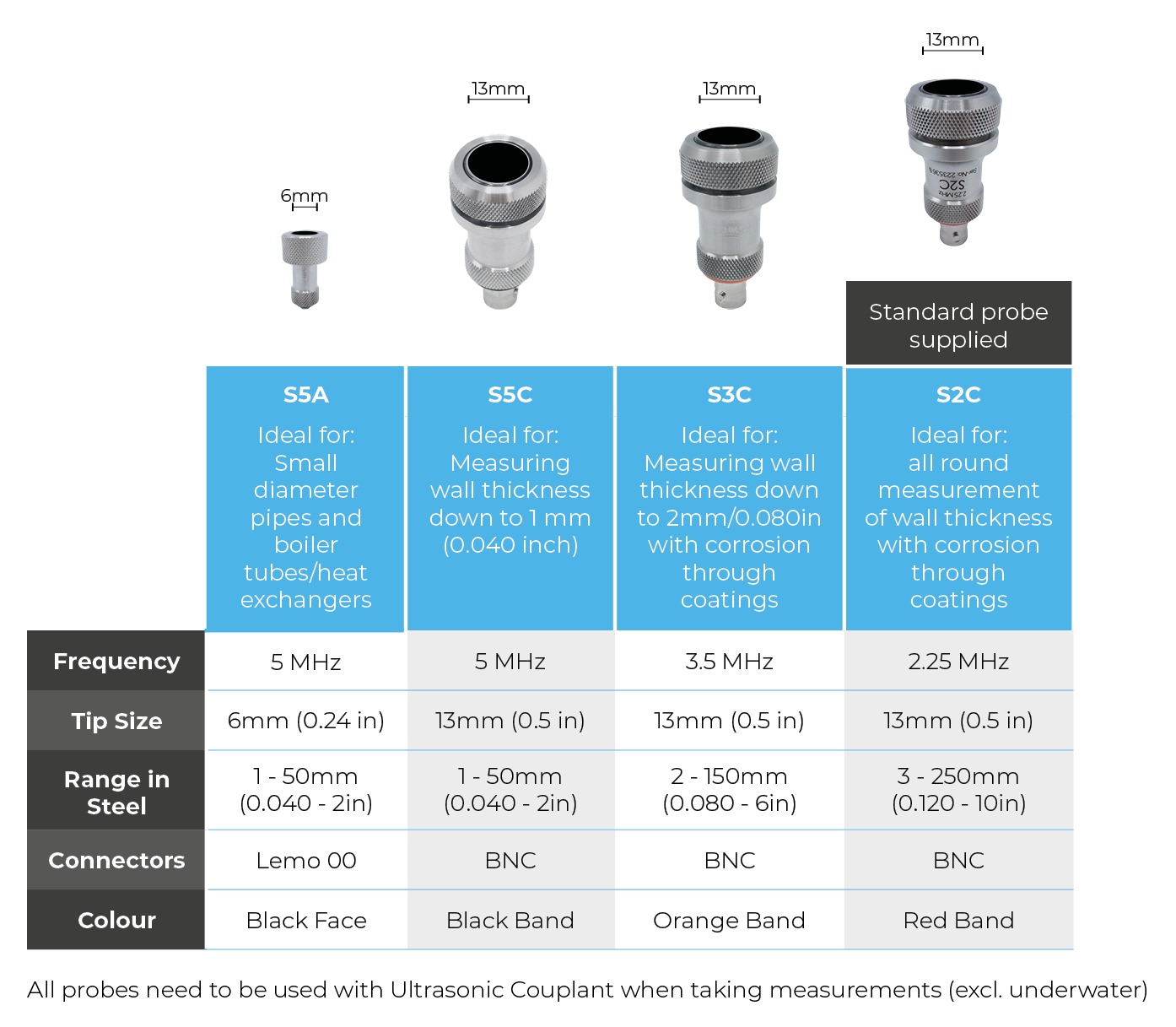

| Probe Options | Single crystal probes |

| Measurement Range in Steel | 1 – 250 mm (0.040 – 10 inch) depending on selected probe and configuration, material and temperature |

| Connector | 2 x Lemo 00 |

| Power | 3 x AA / R6 batteries |

| Battery Life | 10 hours continuous measurement |

| Electronics | Dual channel pulser |

| Display | 2.4 inch QVGA LCD, 47 X 37 mm |

| Size | 84 x 130 x 35 mm (3.3 x 5.1 x 1.4 inch) |

| Weight | 300 g (10.5 oz) (inc. batteries) |

| Operating Temp. | -10°C to 50°C (14°F – 122°F) |

| Environmental Rating | IP67 MIL STD 810G Method 501.6 (high temp +55°C (131°F)) MIL STD 810G Method 502.6 (low temp -20°C (-4°F)) MIL STD 810G Method 507.6 (humidity 95%) MIL STD 810G Method 512.6 (immersion 1 metre for 30 mins) |

| Shock and Impact | MIL STD 810G Method 514.7 (vibration) MIL STD 810G Method 516.7 (shock 20g) MIL STD 810G Method 516.7 (transit drop 1.22 m) |

| Standards | Designed for EN 15317 |

| Compliance | CE, UKCA, RoHS |

| Warranty | 3 years on gauge and 6 months on probe |

| Weight | 5 kg |

| Kit | Cygnus 4 General Purpose Standard Kit WITHOUT PROBE (050-4000/5) |

To compliment our ultrasonic thickness gauges we offer a range of ultrasonic probes. The performance of any ultrasonic thickness gauge relies heavily on the probe and its suitability to the material being measured. Therefore, selecting the right probe is vital. All Cygnus SINGLE CRYSTAL probes are made from stainless steel and include replaceable membranes for long life, requiring no zeroing and have a high linear accuracy.

Cygnus 4 General Purpose Brochure

Cygnus Surface Gauge Family Brochure

Cygnus Surface Range Comparison Guide

Cygnus 4 General Purpose – Consumables Reorder Form

5 reviews for Cygnus 4 General Purpose

Lester

Aug 21, 2016 9:22 AM

Nice

Hashem B.

May 11, 2017 9:23 AM

Reliable, accurate and easy to operate

Nick V.

Jan 26, 2018 9:23 AM

Very good and very pleased

Nick V.

Apr 04, 2018 9:24 AM

I am very pleased with our Cygnus 4 ultrasonic thickness gauge. It works very well, it’s reliable, easy to use and feels like a good quality piece of kit that is well worth the price.

Jagdeep S.

Apr 23, 2020 9:24 AM

Thank you Cygnus. You have been awesome in your support on ALL our inspections for over 20 years. 60 machines including our first machine bought 20 years ago (Cygnus 4, Sr. No 300), are all still in operation. That is a testament to Cygnus’ quality engineering and electronics.